Quick Leads-PCBA

Introduction: The Challenge of PCB Prototyping

Electronics engineers and decision-makers face a tough balancing act when sourcing PCB prototypes. High costs, slow turnaround, and inconsistent quality can derail a project before it even starts. Whether you’re developing a new IoT device, an industrial control system, or a consumer gadget, reliable PCB prototyping is essential.

Unfortunately, many suppliers either charge premium prices for quick service or offer budget options with unreliable quality. This leaves engineers struggling to find a low-cost PCB prototype manufacturer that meets both budget and performance requirements.

The good news? Custom PCB prototyping with no MOQ and fast turnaround times is possible—without compromising on quality. Let’s explore the biggest challenges in the industry and how the right solutions can streamline your PCB development process.

What is a Low-Cost Custom PCB Prototype Service?

A low-cost custom PCB prototype service provides affordable, high-quality printed circuit boards tailored to specific design needs. It ensures fast prototyping, minimal order quantities (No MOQ), and reliable testing. These services cater to electrical engineers and businesses needing quick PCB development for evaluation before mass production. Key factors include cost-effective materials, efficient fabrication processes, and streamlined PCB assembly. Companies like PCBWay and JLCPCB offer competitive pricing with rapid turnaround options.

For decision-makers in electronics manufacturing, balancing cost, speed, and quality is critical. Let’s explore the biggest challenges in PCB prototyping and how to overcome them with the right solutions.

Companies like JLCPCB offer competitive pricing with rapid turnaround options, making them a preferred choice for engineers needing a reliable low-cost PCB prototype manufacturer.

The Biggest Challenges in PCB Prototyping

PCB prototyping is more than just printing a circuit board—it’s about ensuring functionality, manufacturability, and scalability. Here are the most common pain points in the industry:

1. High Manufacturing Costs

- Material Costs: High-quality PCB materials (FR4, Rogers, HDI) can be expensive.

- Small Batch Premiums: Many manufacturers charge extra for low-quantity orders.

- Hidden Fees: Some suppliers add setup, stencil, or tooling costs to the final price.

2. Slow Production Turnaround

- Lengthy Processing Times: Some manufacturers take weeks to deliver a prototype.

- Shipping Delays: Many low-cost PCB prototype suppliers are based in China, leading to customs hold-ups.

- Lack of In-House Assembly: If PCB assembly isn’t included, you waste time sourcing components separately.

3. Quality Inconsistencies & Defects

- Poor Solder Mask Alignment: Cheap PCBs often suffer from misaligned solder masks, leading to short circuits.

- Bad Plating & Via Defects: Low-quality manufacturing can cause broken connections or unreliable vias.

- Electromagnetic Interference (EMI): Improper PCB design can cause signal integrity issues.

4. Component Sourcing Complexity

- Counterfeit or Incompatible Parts: Sourcing components from multiple vendors increases the risk of quality issues.

- Stock Shortages: If critical components are out of stock, your project stalls.

- Logistics Overhead: Managing multiple suppliers adds to time and administrative workload.

Solution: The Right PCB Partner Can Fix These Issues

By choosing a reliable custom PCB prototype supplier, you can avoid these pitfalls and streamline your development cycle. Let’s look at how to optimize PCB costs without sacrificing quality.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

How to Reduce PCB Prototyping Costs Without Sacrificing Quality

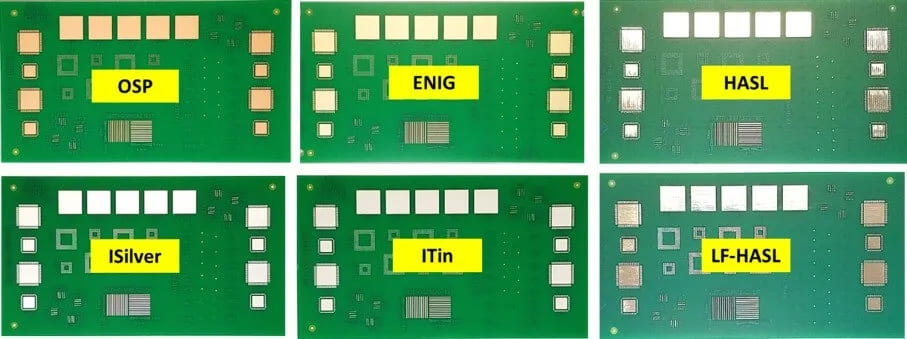

1. Choose the Right PCB Surface Finish

Not all PCB finishes are the same. Some are cost-effective, while others are more durable.

| Finish Type | Cost | Durability | Best For |

|---|---|---|---|

| HASL (Hot Air Solder Leveling) | ✅ Low | ❌ Lower lifespan | Standard applications |

| OSP (Organic Solderability Preservatives) | ✅ Low | ✅ Moderate | High-density designs |

| ENIG (Electroless Nickel Immersion Gold) | ❌ Expensive | ✅ High | Fine-pitch components, aerospace |

💡 Best choice for affordability: HASL or OSP finishes.

2. Optimize PCB Design for Cost-Efficiency

- Reduce the Layer Count – A 2-layer PCB is much cheaper than a 4-layer PCB.

- Use Standard Board Sizes – Non-standard dimensions increase manufacturing costs.

- Panelization – Combining multiple PCBs into a single fabrication panel reduces waste.

For those looking to optimize costs without sacrificing quality, PCBWay provides affordable PCB prototyping with fast turnaround, including small-batch production and various PCB surface finish options.

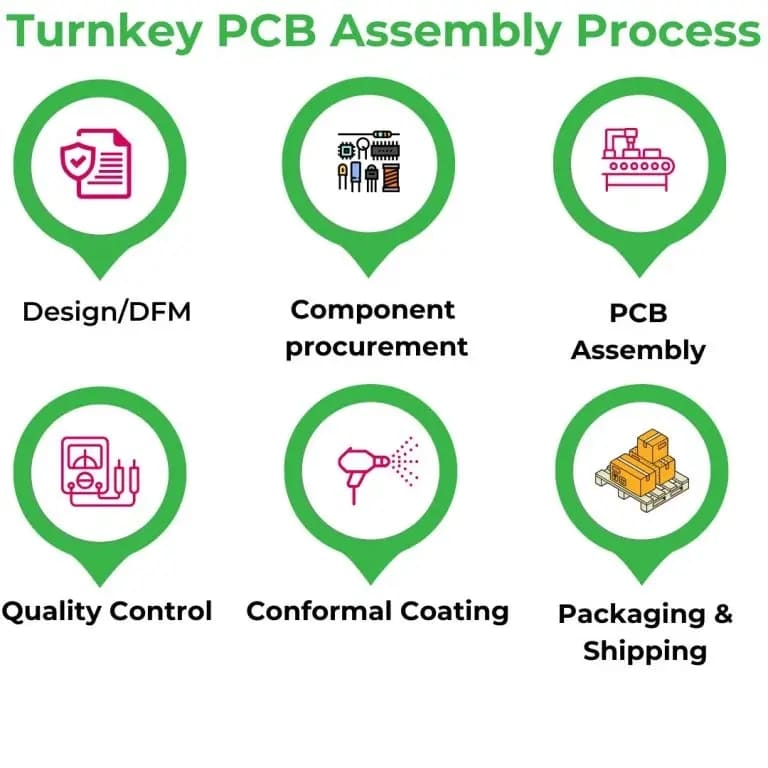

3. Use a Turnkey PCB Prototype and Assembly Service

- No MOQ (No Minimum Order Quantity) – Avoid over-ordering to meet supplier requirements.

- Integrated Component Sourcing – Reduces shipping costs and delays.

- Faster Prototyping Cycles – Get a fully assembled PCB without dealing with multiple vendors.

Reducing PCB prototyping costs doesn’t mean sacrificing quality. By choosing the right materials, optimizing panelization, and working with a reliable low-cost PCB prototype manufacturer, you can significantly cut costs. Check out this detailed guide on how to save money on PCB assembly for practical cost-saving techniques.

Why Are Custom PCBs Expensive? Industry Breakdown

Many engineers ask, “Why are custom PCBs so expensive?” The answer lies in three key cost factors:

1. Material & Layer Costs

- High-end materials (like Rogers 4003C or Isola FR408) are costly but necessary for high-speed circuits.

- Multilayer PCBs (4+ layers) require complex manufacturing steps, increasing production costs.

2. Manufacturing Complexity

- Fine-Pitch Components – High-density components (like BGA or QFN packages) require precise manufacturing.

- Via-in-Pad Technology – Advanced microvia structures add fabrication difficulty.

3. Assembly & Labor Costs

- Manual Assembly vs. Automated SMT – Hand-assembled prototypes cost more due to labor costs.

- Component Lead Time – Shortages of chips like MCUs and FPGAs drive up costs.

High-Quality PCB Prototyping with Testing: Ensuring Reliability

Even low-cost PCB prototypes need rigorous testing to ensure performance. Here’s how:

1. Design for Manufacturability (DFM) Checks

- Ensures the PCB meets production standards before manufacturing.

- Reduces rework and scrap rates.

2. Electrical & Functional Testing

- In-Circuit Testing (ICT) – Checks for open circuits, shorts, and resistance issues.

- Flying Probe Testing – Ideal for low-volume PCB fabrication and assembly service.

- X-ray Inspection – Used for BGA and hidden solder joint analysis.

Skipping PCB testing can lead to defects, short circuits, or early product failure. To ensure high-quality PCB prototyping with testing, methods like flying probe, in-circuit testing, and X-ray inspection are essential. Want to dive deeper? Here are the top 5 PCB testing methods every engineer should know.

FAQs

1.What’s the cheapest way to get a PCB prototype?

The cheapest way is to use a low-cost PCB prototype manufacturer that offers No MOQ, panelization, and HASL surface finishes. You can also opt for 2-layer designs and standard board sizes to save costs.

2.Can I get a high-quality custom PCB prototype without spending too much?

Yes! Choose a custom PCB prototyping no MOQ service with functional testing, fast turnaround, and DFM analysis. This ensures low-cost PCB prototyping with fast turnaround while avoiding manufacturing defects.

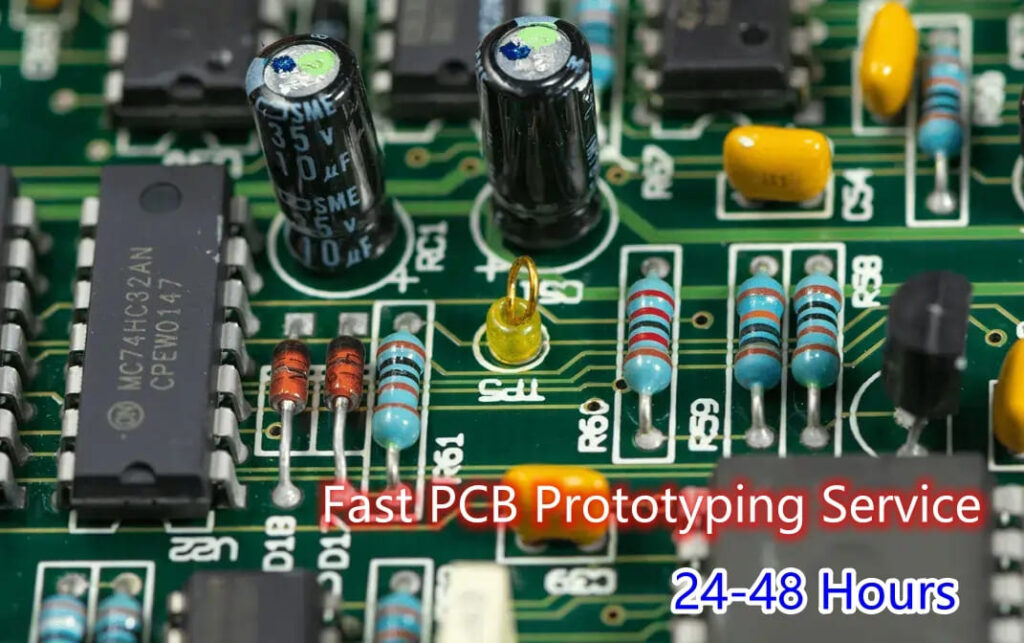

3.How fast can I get a PCB prototype made and assembled?

With the right turnkey PCB prototype and assembly service, you can get prototypes in 24-48 hours. If you also need PCB assembly, the entire process typically takes 5-7 days depending on component availability.

4.What’s the best place to order custom PCB prototypes online?

Look for trusted suppliers with instant online quoting, a track record of high-quality PCB prototyping, and services like:

- Prototype PCB fabrication and assembly service

- Affordable PCB prototyping with fast turnaround

- Quick PCB prototyping for electronic design engineers

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion: Finding the Right PCB Supplier

A fast, affordable PCB prototype service is essential for engineers and businesses looking to accelerate product development. Choosing the right supplier can help you reduce costs, improve turnaround times, and maintain high-quality standards.

If you need affordable PCB prototyping with fast turnaround, look for:

✅ No MOQ custom PCB prototyping

✅ Integrated PCB assembly & component sourcing

✅ Turnkey PCB services for hassle-free production

Ready to streamline your PCB prototyping? Explore our services today and experience high-quality, low-cost PCB prototypes with a fast turnaround!

Not all PCB suppliers offer the same level of quality, speed, and pricing transparency. If you’re sourcing from overseas, it’s crucial to vet manufacturers carefully to avoid delays or defective PCBs. Check out this expert guide on choosing a reliable PCB supplier in China to make an informed decision.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!