Quick Leads-PCBA

Engineers often hit a wall when prototyping: long lead times, high costs, and manufacturers demanding minimum order quantities. That’s frustrating when all you need is a few boards to test your idea. We’ve been there too. That’s why we created a no MOQ PCB prototype solution that delivers fast turnaround, tested boards, and flexibility — exactly what hardware teams and engineers need to move fast and build smart.

What is a No MOQ PCB Prototype Service?

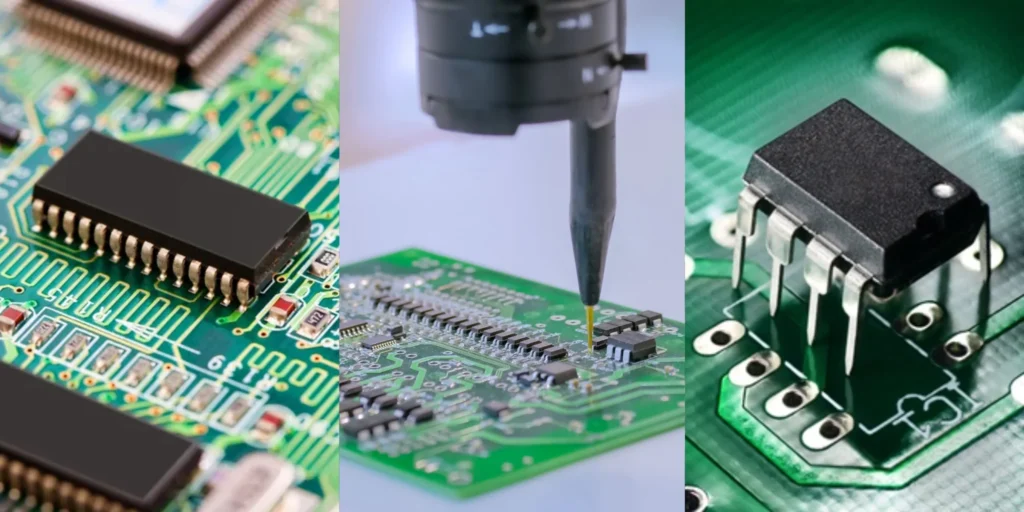

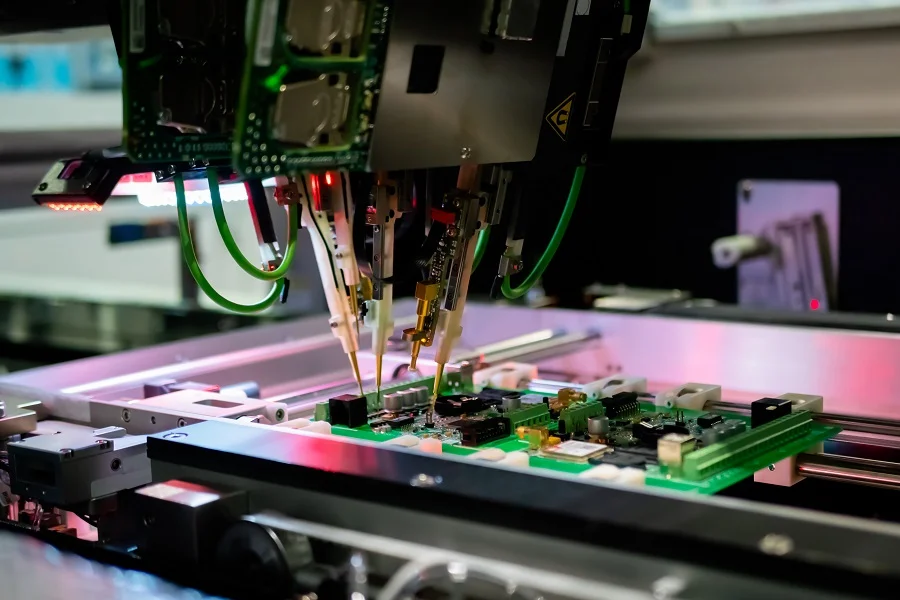

A no MOQ PCB prototype service lets you order as few as one PCB with full manufacturing, testing, and delivery support. Whether you’re a hardware startup, an R&D team, or an IoT product developer, this model cuts your cost and lead time drastically. We offer fast PCB prototyping with assembly (SMT & THT), DFM checks, and quick delivery — no quantity constraints, no waste.

>Why Traditional PCB Prototyping Slows Innovation

Most PCB manufacturers prioritize high-volume orders. That means:

-

MOQ restrictions that block engineers from quick prototyping

-

Slow turnaround that delays testing cycles

-

High setup costs even for simple changes

These problems create a bottleneck. And if you’re a startup or a solo engineer? Forget it — you’re priced out before you even begin.

Here’s what engineers are saying:

-

“I just needed five test boards — they wanted 100 minimum!”

-

“Changing a single component meant redoing everything — and waiting two weeks.”

-

“We spent more on prototypes than on our actual launch!”

This is exactly why low-volume and small batch PCB prototype services are gaining traction.

How Our No Minimum Order PCB Prototyping Empowers Engineers

Whether you’re building a wearable, an industrial sensor, or a custom controller, our no MOQ policy lets you go from idea to hardware with zero friction.

Benefits:

-

Start with just 1 board – test, learn, repeat

-

Save budget for what really matters: iterations and design

-

No waste, no unused inventory

Fast PCB Prototyping Without Sacrificing Quality

We get it — fast is good, but fast + accurate is better. Our process is designed to deliver tested PCB prototypes in 24–72 hours, with:

-

Full DFM/AOI inspections

-

Lead-free RoHS-compliant processes

-

Gerber file and BOM verification

-

SMT and THT options

What you get is a board that’s not just fast — it’s right the first time.

Quick Turn PCB Prototypes for Complex Industrial Projects

Industrial applications — robotics, telecom, control systems — demand:

-

Fast iteration cycles

-

Precision fabrication

-

Long-term reliability

We specialize in quick turn PCB prototype services tailored for industrial electronics. Engineers trust us because we not only deliver fast, but we also get the complexity right.

Low Volume PCB Assembly with Full Testing Support

When you need low volume PCB assembly, we offer everything from:

-

SMT/THT component sourcing

-

Functional testing

-

ICT/Flying probe

-

AOI and X-ray inspection

And because we support custom PCB assembly no MOQ with testing, you get full functionality assurance — whether you’re making 5 boards or 50.

Unit Circuits: Leading PCBA Manufacturer

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA Low MOQ & Fast Turnaround

Low MOQ & Fast Turnaround Prototype & Mass production

Prototype & Mass productionLimited Time Offer:

Get $100 off your order TODAY!

Rapid PCB Fabrication for IoT & Consumer Hardware

IoT devices and smart consumer products have tight windows for prototyping and launch. Our rapid PCB fabrication line helps you stay ahead with:

-

24-hour build times

-

Flexible multi-layer PCB capability

-

Component placement down to 01005

We also offer prototype PCB assembly service for IoT devices, so your connected product is ready to ship — fast.

Turnkey PCB Prototype Service: From Design to Delivery

Our turnkey PCB prototype service is built for engineers who want to:

-

Upload Gerber/BOM

-

Approve instant DFM feedback

-

Receive fully assembled boards in days

From PCB design to prototype, we handle everything — component sourcing, soldering, testing, and delivery.

Why Hardware Startups Prefer Small Batch PCB Prototyping

Startups don’t need 500 PCBs upfront. They need:

-

Fast validation of ideas

-

Flexibility to iterate

-

Smart budgeting

That’s why we focus on small batch PCB prototype orders — with the same care as large runs.

Comparison: Why Startups Choose Us vs. Traditional Houses

| Feature | Our Service | Traditional PCB House |

|---|---|---|

| MOQ | 1 board | 100+ |

| Turnaround | 24–72 hours | 5–10 business days |

| Testing Included | AOI, Functional, Flying Probe | Often Extra $$$ |

| IoT/Startup-Focused Design | ✅ Yes | ❌ Not prioritized |

| English Support | Dedicated engineer support | Basic sales response |

What Makes a Great China PCB Prototype Manufacturer?

Here’s the reality: not all China EMS providers are created equal. So let’s compare your options.

Comparison: Us vs. ALLPCB & JLCPCB

| Feature | Our Service | JLCPCB | ALLPCB |

|---|---|---|---|

| MOQ | 0 (No minimum) | 5–10 boards | 5–10 boards |

| Assembly Testing Included | ✅ Full testing | Optional (extra $) | Optional |

| Turnaround Speed | 24–72 hours | 3–7 days | 3–5 days |

| Dedicated Engineer Support | ✅ 1:1 chat/email | Mostly ticket-based | WeChat only |

| Ideal for Startups | ✅ Yes | ❌ Not always | ⚠️ Mixed feedback |

How to Get PCB Prototypes Fast Without Compromising Cost

Quick prototyping doesn’t have to be expensive. You can save money without sacrificing reliability by:

-

Choosing a no MOQ vendor

-

Using turnkey services to cut logistics

-

Avoiding rework through DFM and functional testing

We’re often asked: “how to get PCB prototypes fast with low cost?” — and the answer is: work with a manufacturer that actually understands engineering.

The Technical Side: Solving Assembly Issues (SMT/THT, RoHS)

We’ve helped teams solve:

-

Cold solder joints on fine-pitch ICs

-

Component sourcing delays

-

Misaligned BGAs

-

RoHS compliance failures

Our SMT lines are built for small quantity PCB manufacturing, and our engineers inspect every file before a single board is made. Whether it’s RoHS-compliant PCB prototypes or mixed assembly needs — we’ve got you covered.

Whether you’re building with SMT, THT, or a mix of both, each method offers unique advantages depending on your component density and board complexity. For a deeper look at how SMT works in practice, check out our detailed guide to SMT assembly.

Tested PCB Prototypes: Why QA Can’t Be Skipped

What good is a prototype that doesn’t function?

We run every board through AOI, functional tests, and flying probe checks — no exceptions.

A tested PCB prototype saves time and trust — because if your first sample fails in the field, the cost is 10x later.

We don’t just build fast — we build right. Every board goes through visual, functional, and automated testing. You can explore the top PCB testing methods here to understand how we verify performance before delivery.

From PCB Design to Prototype: Closing the Gap

Prototyping is part of the product development cycle, not an afterthought. That’s why we help clients close the gap between PCB design to prototype:

-

Gerber review + BOM validation

-

On-demand feedback

-

Design tweaks to fix DFM violations

And yes — we offer PCB turnaround time as fast as 24 hours, even for multi-layer boards.

Why Engineers Recommend Us for No MOQ PCB Assembly

Our reputation comes from real results. Engineers trust us because:

-

We deliver what we promise

-

We answer questions with technical insight

-

We treat small runs like big launches

We’re often called the best small batch PCB prototyping company by our repeat clients. And they come back because we help them launch faster, smarter, and better.

FAQs

1.Why is PCB prototyping important before full production?

PCB prototyping lets engineers identify design flaws, test circuit functionality, and avoid costly mistakes before scaling. Without a working prototype, issues in the schematic or layout may go undetected. Our PCB prototyping service for hardware startups ensures your board functions correctly before mass production — saving both time and money.

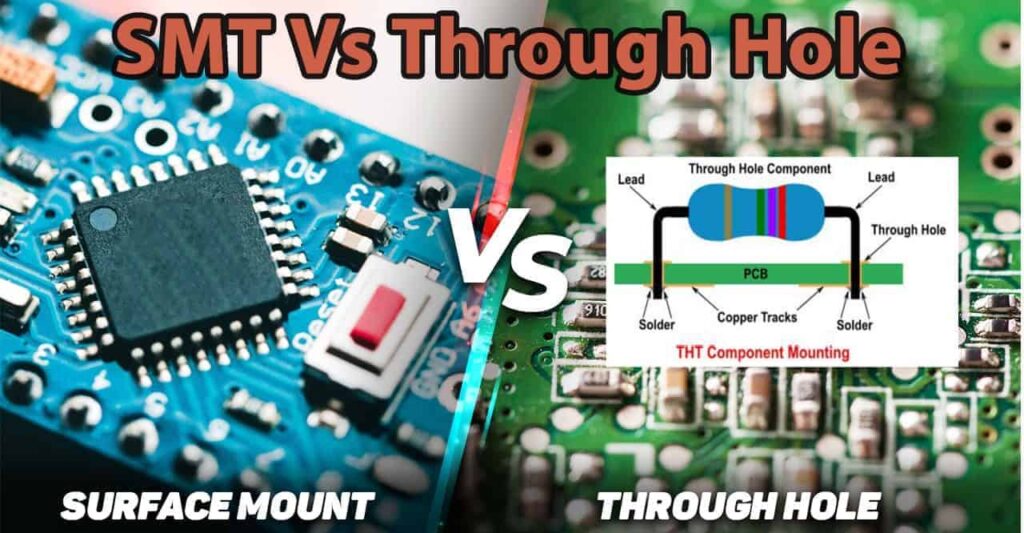

2.What’s the difference between SMT and through-hole PCB assembly?

SMT (Surface Mount Technology) places components directly onto the PCB surface, while through-hole assembly uses leads inserted through holes. SMT is ideal for rapid PCB fabrication and compact designs, while through-hole offers stronger mechanical bonding. We support both SMT and THT for custom PCB assembly with no MOQ needs.

3.Why does PCB assembly seem expensive for small orders?

PCB assembly costs can seem high for low quantities because setup, stencil, and test procedures are fixed costs. That’s why our low volume PCB assembly service is designed to reduce overhead with efficient workflows, making cheap fast PCB prototyping with quality assurance possible — even for just a few boards.

4.What is the difference between prototype and rapid prototype PCBs?

A prototype PCB is your first working version for function testing. A rapid prototype PCB is built with speed in mind — often within 24–72 hours. Our quick turn PCB prototype service combines both: fast delivery and functionality, so you get tested hardware quickly, even in small batch PCB prototype runs.

Have Specific Requirements?

Looking for high-precision PCB assembly for your products? Our team specializes in delivering top-tier assembly services, ensuring your devices perform flawlessly in any environment. Contact us today for a free consultation on how we can enhance your product’s reliability.

Conclusion

Speed, flexibility, and quality aren’t optional — they’re essential. With our no MOQ PCB prototype and fast delivery service, engineers can test faster, build better, and move to market with confidence. Ready to start your prototype journey? Reach out for a quote — and let’s build something brilliant together.

Save on your next PCB project?

Claim $100 OFF your order today.

✅ high-quality PCB assembly with strict quality control ✅ ISO-certified & 8+ years of experience. ✅ Low MOQ, fast turnaround, and 100% E-tested PCBs.

Additional Resources:

- How to Repair Circuit Boards: A Step-by-Step Beginner’s Guide

- Capacitor on Circuit Board: A Comprehensive Guide

- What Are PCB Conformal Coatings? Types, Benefits, and Applications Explained

- SMD Size Codes Explained: A Complete Guide to Understanding Surface-Mount Component Dimensions

- AC vs DC: Key Differences, Applications, and Advantages in Modern Electronics

Request for Quote

RECENT POSTS

PCB Transformer Explained: Types, Working Principle, and Design Tips

Discover how PCB transformers work, their key types, and design integration tips. Learn to select

Why Smart OEMs Avoid Cheap PCB Assembly: 5 Hidden Risks That Cost More

Avoid costly mistakes in OEM projects. Discover why cheap PCB assembly risks quality, compliance, and

RELATED POSTS

Leading PCBA Manufacturer

✅ Assemble 20 PCBAS for $0 ✅ Get $100 OFF – Risk-Free Trial!

✅ 100+ Satisfied Customers

✅ Ensured Quality & On-Time Delivery

✅ Free Trial, No Commitments!