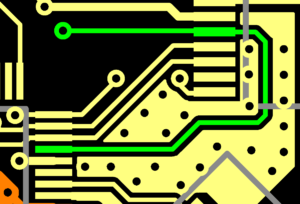

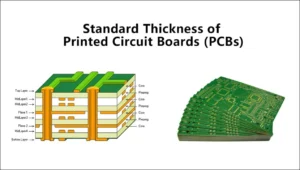

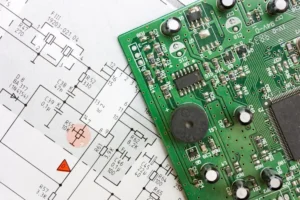

An Introduction to 2 Layer PCB: Structure, Benefits, and Manufacturing Tips

Learn what a 2 layer PCB is, how it works, key benefits, layout rules, and manufacturing tips to cut cost. Validate your design faster and get reliable, low‑cost 2 layer PCB assembly support today.

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA