Quick Turn Turnkey PCB Assembly: Fast Quotes, Faster Prototypes, Lower Risk

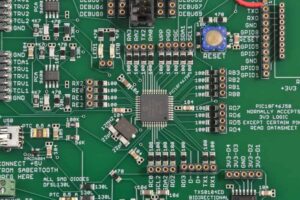

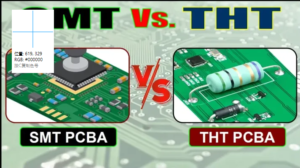

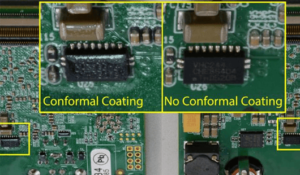

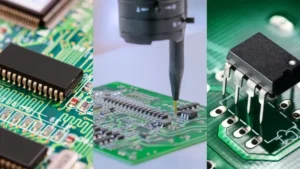

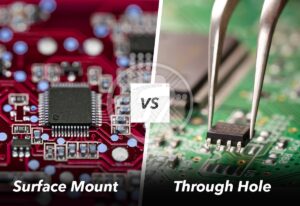

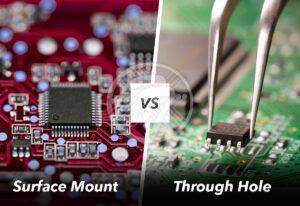

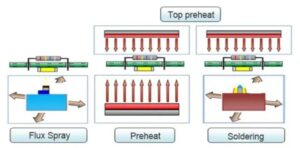

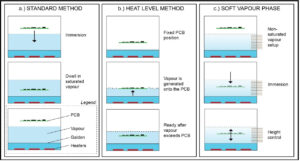

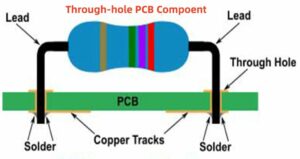

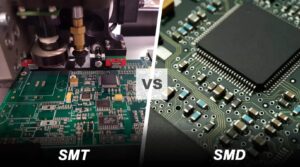

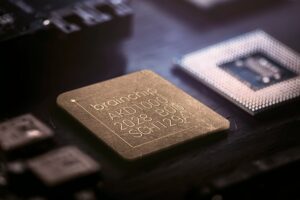

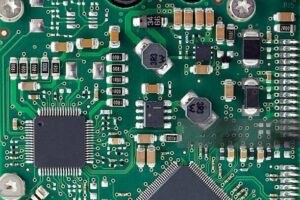

Quick turn turnkey PCB assembly for engineers who need fast quotes, reliable component sourcing, controlled SMT/DIP processes, and verified prototypes. Reduce risk, avoid platform pitfalls, and move from design to working boards faster.

ISO-certified & 8+ years of PCBA

ISO-certified & 8+ years of PCBA