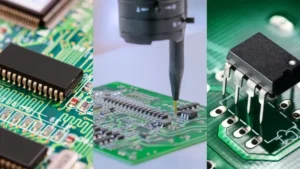

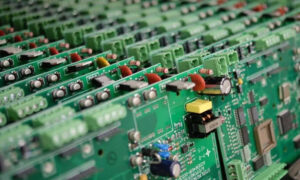

How Multilayer PCBs Revolutionize Medical Equipment Technology in Healthcare?

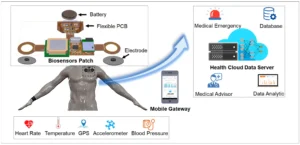

In this article, we’ll look at how multilayer PCBs are changing medical technology by making small, reliable, high-performance devices. We’ll talk about how they’re used in diagnostics, wearable tech, implants, and IoT.

Assemble 20 PCBAS for $0

Assemble 20 PCBAS for $0